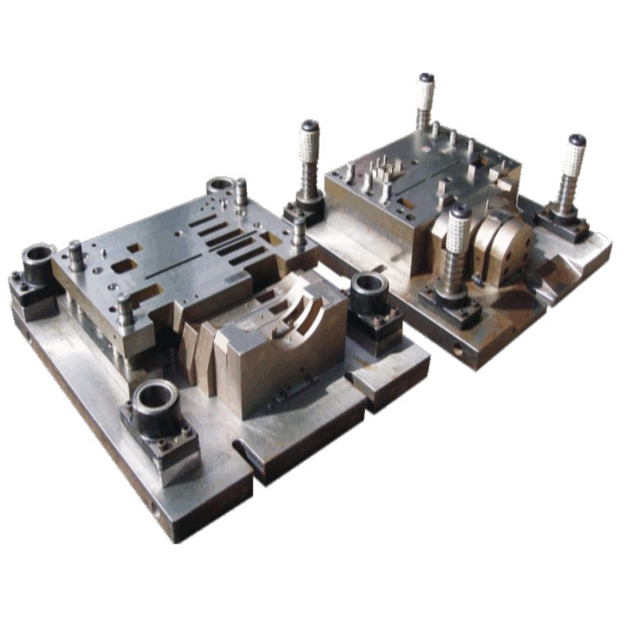

HOT STAMPING MOLD:

CONTACT FOR QUOTE 0901 819950

DETAILED DESCRIPTION:

What is a hot stamping die?

What is a hot stamping die?

Hot stamping mold is a type of mold used to process metal under pressure in a hot state to shape products.

Hot stamping molds are mainly used to shape products at high temperatures, so the components of the hot stamping mold must be able to withstand high temperatures, have strength, hardness, and durability to shape the product.

Requirements for hot stamping mold materials are moderate hardness, high strength and toughness, 35 – 46 HRC, high abrasion resistance, high temperature resistance (can be in contact with the workpiece).

hot up to 10000 0C).

ADVANTAGES AND DISADVANTAGES OF HOT STAMPING METHOD:

Advantage

+ Can produce large parts of any shape.

+ The stamped product has high mechanical strength.

+ The product has high gloss and precision.

+ High productivity applying mechanization and automation.

Defect

+ The cost of mold manufacturing is high because the material used to make the mold is alloy steel.

+ The mold cavity is difficult to manufacture and must use specialized machines

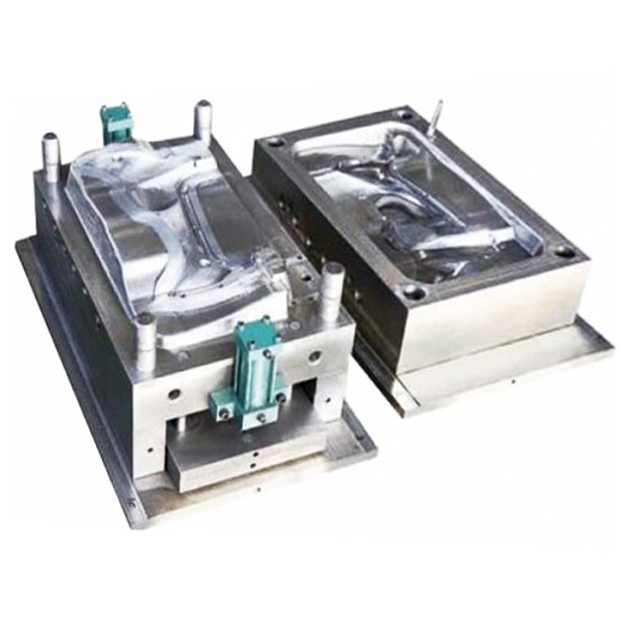

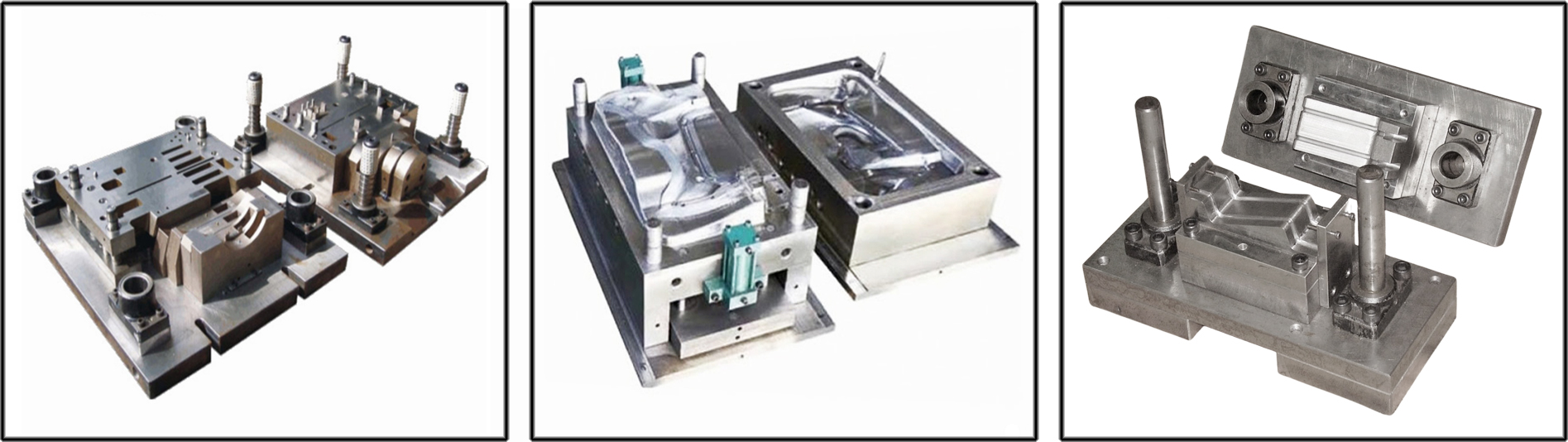

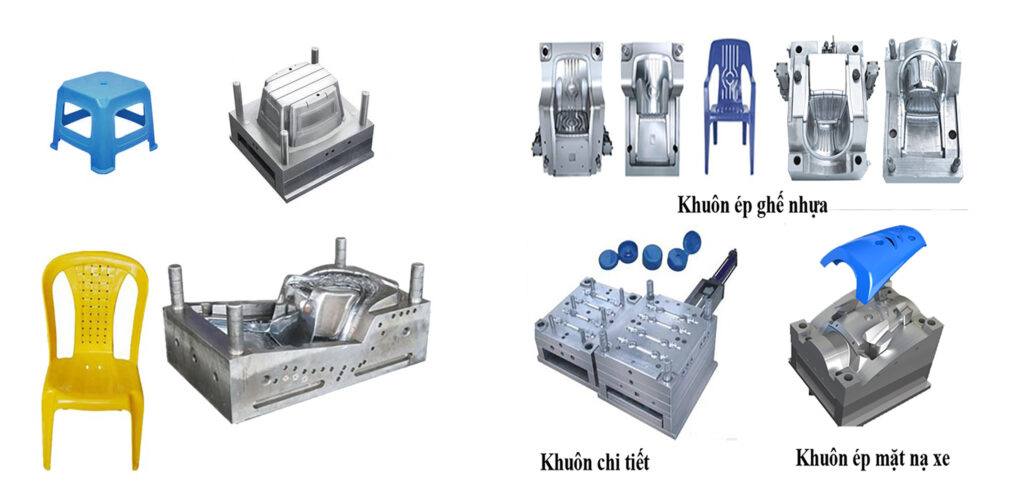

AN TRAN PLASTIC is equipped with a synchronous and modern system of factories, production lines and equipment imported from the US, Western European countries, Japan and some newly industrialized countries (NICs) with mechanical qualifications. Relatively high level of globalization and automation. Products are manufactured from different plastic raw materials such as: PVC, ABS, PP, PA, HDPE, PS, PET… There are also diverse sizes and colors. Specializing in designing and manufacturing injection molds in the field of industrial and household plastics

5 reasons for you to choose AN TRAN PLASTIC:

1. Good team

Our experienced design engineers and mechanical engineers are fully capable and always dedicated to advising customers from creating creative design ideas, balancing mold making costs to suit their needs. bridge to complete manufacturing and put the mold into stable operation.

2. Flexible price

We help customers find suitable mold design solutions and options with reasonable processing costs; Flexible customization according to requirements, size, type of business, industry and product type.

3. Mold is durable

Understanding that mold processing is a high-value production segment that requires precision in details, we are equipped with modern machinery systems to be able to process high-quality molds, made from materials. High quality ensures durability during long periods of use.

4. High aesthetics

The mold is carefully polished to avoid concave errors, ensuring smoothness, helping the plastic product to be shaped evenly and meet the required aesthetic standards.

5. Trendy

Besides respecting customers’ opinions and complying with requests, our design team always updates the latest trends that are popular in the market to proactively propose ideas to customers. create and improve beautiful designs that suit user tastes.

Quy trình thiết kế và gia công khuôn của AN TRAN PLASTIC:

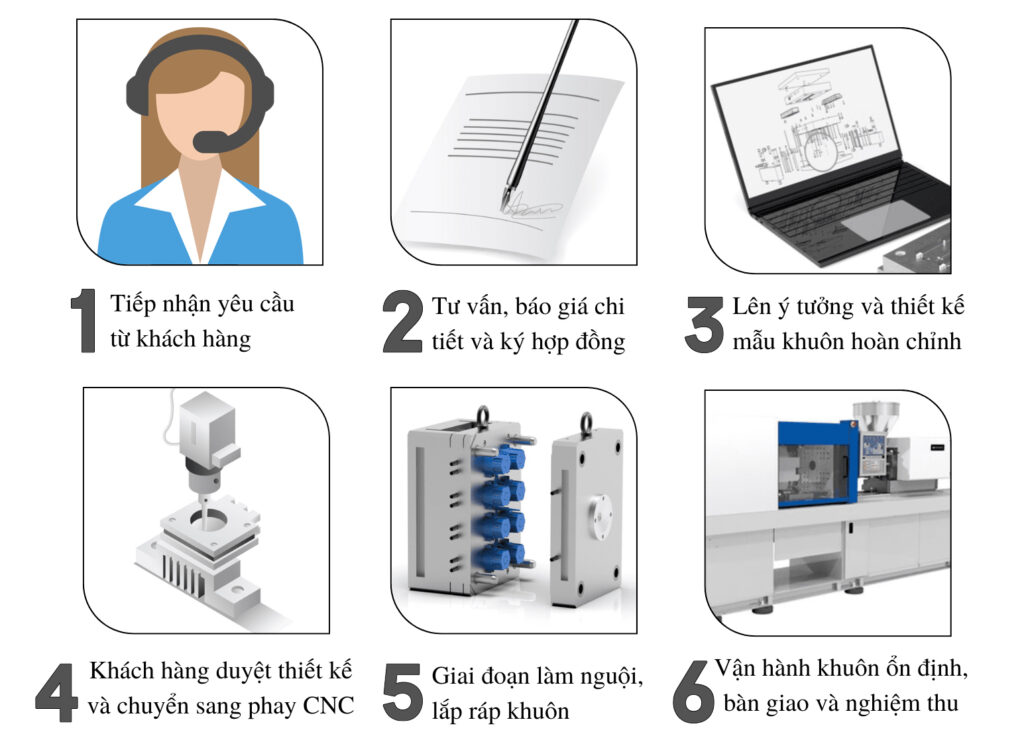

Step 1: Receive requests from customers.

Step 2: Consult for a detailed quote and sign a contract.

Step 3: Come up with ideas and design a complete mold model or according to available sample products provided by the customer.

Step 4: The customer approves the design and switches to CNC milling (Mold processing).

Step 5: Cooling stage, mold assembly.

Step 6: Stable mold operation, handover and acceptance.

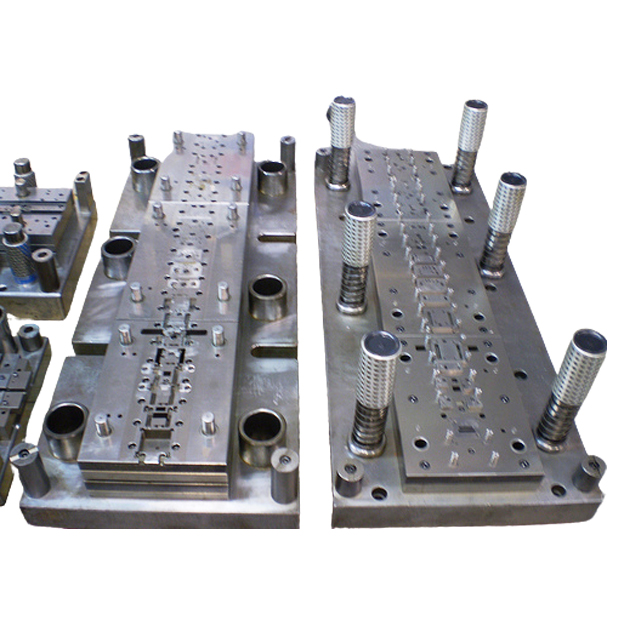

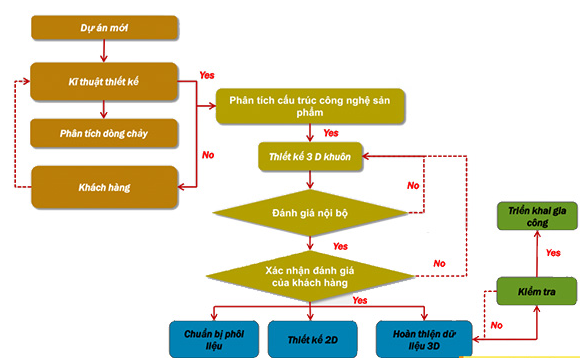

Hot stamping die design and processing process:

– To be able to make molds that meet technical requirements such as ensuring the accuracy of the shape and size of the product, and allowing the product to be easily removed from the mold, the mold must Having a reasonable structure, not too complicated to suit the intended use, etc., the mold design and processing process is a very important factor that determines the quality of the mold.

– The mold design and processing process is very important. The process of designing and machining accurate molds will help produce high quality plastic products.

Email: ads.antranplastic@gmail.com

CONTACT: 0901.819.950